How Do Kanban Cards Work

Kanban, one of the primary Lean tools, is an inventory management system that relies on real-world inventory consumption (demand) to trigger replenishment signals (supply). Click here to read more about kanban.

When a kanban bin is opened (break a bin) or emptied (empty a bin), a replenishment signal is sent to the supplier to order the standard quantity at the standard lead time. Click here to read about kanban timing, e.g., empty a bin or break a bin, along with kanban types (1-card, multi-card, and 2-card solutions.)

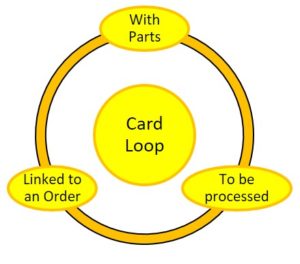

3 Status choices for kanban cards

A kanban card spends its life in one of 3 states.

- Kanban cards are linked to on-hand inventory. For break-a-bin items, the card stays with inventory until the first piece is removed from the bin. For empty-a-bin items, the card stays with inventory until the last piece is removed from the bin.

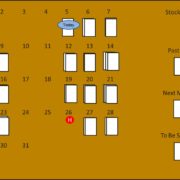

- Kanban cards hang on a kanban board while waiting for a supplier shipment. Click here to read about kanban boards.

- Kanban cards are in limbo for a short time between when they are delinked from inventory, or turned in to be processed, and when they are linked to a new replenishment order.

HINT: It should take no more than 4 hours from the time a card is turned in until it is processed to generate a replenishment order.

How kanban cards work

- As inventory is consumed, kanban cards are triggered. Some sites use break a bin, where the first piece out of a kanban bin triggers an order, and other sites use empty a bin, where the last piece out of a bin is what triggers an order triggered. Click here to read about trigger timing.

- Kanban signals are transmitted to the item’s supplier, which can be an internal manufacturing cell or an external supplier. For internal suppliers, sometimes the card actually travels to the supplying work cell, but the signal can also be electronic, such as an open purchase order or an email request.

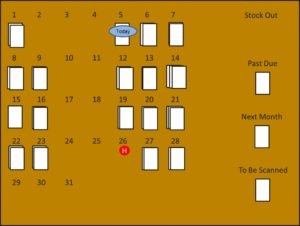

- While waiting for material from the supplier, the kanban card hangs on a kanban board, seen in picture below. Each card hangs on the numbered peg that stands for the due date for that order. Click here to read about kanban boards.

- When replenishment material arrives, the associated card is taken from the board and placed with the material in the correct storage location.

This trigger-and-receipt process is repeated over and over for every kanban item.

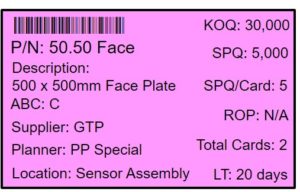

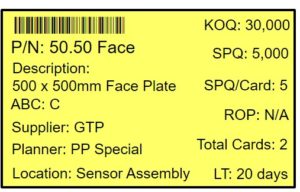

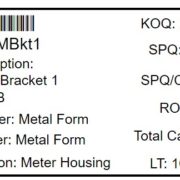

Design your kanban cards

A kanban card is a signal to order material and therefore it should include the basic information about the item and its kanban solution.

- Part number

- Description

- Supplier

- Lead time

- Kanban order quantity (KOQ)

- Standard package quantity (SPQ)

- Number of containers per card

- Total number of cards

- Storage location

- Reorder point (only required for 1-card solutions)

This is an example of a kanban card.

Several other items can be included on the card to help with processes on the floor or when processing the card.

- Barcode, if the card is scanned to generate a new order

- Revision date of the card, to make it easier to sort old cards from new cards when deploying updated cards to the floor

- ABC classification

- Supplier part number, if different from the in-house identifier

- Planner or buyer, the person who manages this item

Cards should be no smaller than about 2” x 3” (picture a business card or credit card) and no larger than ¼ of a sheet of paper. Card size has a direct impact on the amount of space required for kanban boards, so don’t make cards too large!

Spike cards

Sometimes an item or work cell experiences a temporary increase in demand that doesn’t justify resizing kanban solutions, but supply must increase for a while to support the higher demand. The most common driver for spike cards is past-due shipments that must be accelerated through the plant, necessitating an increase in daily output.

Spike cards are handled differently than regular kanban cards. When spike cards are deployed, the “spike” inventory always goes at the back of point-of-use storage, to ensure that regular inventory is consumed first. This ensures that regular kanban cards continue to be processed at the regular cadence.

Spike cards are turned in just like regular cards, but they should not be automatically processed to place new orders, since the increase in demand is not a permanent condition. Remember, if the increase in demand is permanent or for an extended period of time, kanban solutions are resized “up” to provide a high level of supply.

Card material & color

Most kanban cards are paper or plastic.

- Plastic cards are the best because they’re durable, easy to print, they require no secondary processing (no cutting, laminating, or sleeves), associates can write on back with grease pen, the card-type can be used for other purposes (employee or visitor badges), and they come in different colors. The disadvantage is that they require special card stock and a printer.

- Paper cards must be modified to make them durable, such as laminating or putting them in plastic sleeves. The advantages for paper cards include the ease of using different colors and the ability to size cards to match desired layout. The disadvantages are significant. They require additional processing (cut printed sheets into individual cards then laminate them or put in clear plastic sleeves), they are not easy to print because printing requires the user to create sheets of cards to print, but different part numbers require different numbers of cards. Most people are surprised just how much work it takes to print paper cards and get the ready to deploy – even a couple hundred cards can take a day to prepare.

- Some sites attempt to use electronic or virtual cards, and this generally doesn’t work because it removes the process and employee-engagement benefits that are gained from the visual aspects of kanban.

It is beneficial to use different colors to indicate various card categories.

- Purchased items are often a different color than manufactured parts. This makes it easier to find cards as orders arrive at the work cell, because a stack of cards on a specific due-date peg is easily divided into external and internal cards. This is also helpful if different people manage internal versus external items.

- Spike cards should be a bright color that stands out from a distance. Since they are not automatically reordered, they don’t need a barcode.

- Material that goes to an external process, like plating or heat treat, or material from specific suppliers can be a designated color to help track those items throughout the site.

- Material for a particular work area or product family can be a specific color, particularly if kanban contacts are assigned by work cell or value stream.

A purchased item might have a pink card for regular kanban and a yellow card for spike inventory.

Kanban cards are the most common replenishment signal because they’re easy to use, they have visual-management advantages, and they can provide instant access to item data and kanban insights with the right card content.

Need more info? Keep browsing this blog. Want specific expertise implementing kanban solutions in your organization? Contact Josette Russell today.

Kanban is a repetitive loop

Kanban is a repetitive loop