Replenishment Methods

There are four basic methods that can be used to trigger replenishment orders for items that are held in stock.

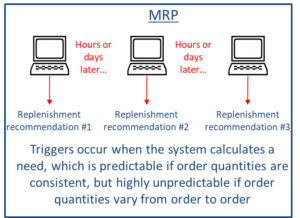

MRP – Materials Requirements Planning

Materials Requirements Planning (MRP) is one of the most common replenishment methods. It uses system data to generate MRP recommendations or take automated actions to order purchased or manufactured items. The logic for MRP is simple:

Demand during the defined time period – current balance – expected receipts in the time horizon = required quantity to order.

The GIANT weakness in any MRP system is the complete dependence on system data: errors in customer orders or forecast, on-hand balance, bills of material, or incoming receipts can result in the wrong MRP recommendation.

Other common weaknesses include the inability to round for minimum order or standard package quantity limits, so it creates an order that supplier won’t accept, or logic that can assign a due date that the supplier can’t meet.

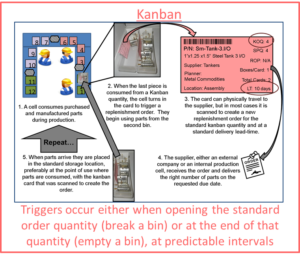

Kanban

Kanban is a visual replenishment system based on actual consumption, not system data. Kanban activity occurs at point of use (POU) and therefore it covers many of the errors that derail MRP (e.g., on-hand balance, backflushing, tracking open orders) because it puts the replenishment process in the midst of consumption activity, especially if kanban orders are triggered at point of use.

The biggest challenge or weakness in most kanban systems is the sizing process, or getting correct kanban solutions.

Kanban generally uses a visual signal, such as a kanban card or empty tote, to signal the need for replenishment.

VMI – Vendor-Managed Inventory

Vendor-managed inventory (VMI) is on-site inventory that is reviewed and refilled by the supplier on a defined cadence, generally once or twice a week. VMI is similar to kanban because refilling the bin is based on actual consumption, with no system dependence.

The biggest potential weakness for VMI is allowing over-sized bins to be over-filled by an over-eager supplier, thereby increasing on-hand inventory.

Consignment

Consignment inventory isn’t owned by the operation until it’s “opened” or pulled into use. This reduces on-hand dollars by delaying the ownership transaction, but no space reduction occurs. In fact, required space often goes up if the supplier prefers to ship larger quantities.

Consignment can work well for overseas suppliers that want to save freight by shipping full containers, and they are willing to delay invoicing as product is pulled into production.

The biggest risk or weakness with consignment inventory is managing the transfer of ownership. To meet financial requirements and to be fair to the supplier, inventory must become the property of the receiving site before it is consumed, and not at the time it is backflushed.

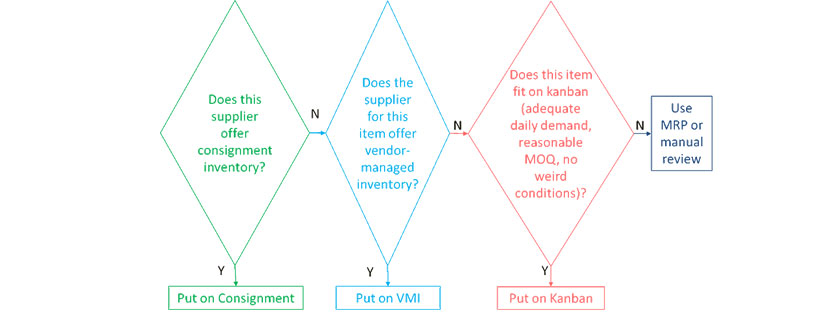

Which method?

Consignment reduces the financial impact of on-hand inventory, which is a huge benefit.

VMI reduces the effort required to manage inventory, which is a productivity benefit.

Kanban is a streamlined way to manage inventory and it also protects on-hand inventory from system errors.

MRP should be the last choice.

Trackbacks & Pingbacks

[…] Click here to read about replenishment methods: MRP, kanban, VMI, and Consignment. […]

Comments are closed.